|

Hongning CHEN and Yi-Chun LU, Department of Mechanical and Automation Engineering, CUHK

Prof. Yi-Chun LU and her research team recently proposed and demonstrated a flow cathode that exploits highly concentrated sulphur-impregnated carbon composite, to achieve high catholyte volumetric capacity, battery energy density, cycle life (>100 cycles), columbic efficiency (>90%) and energy efficiency (>80%). The approach achieved the highest catholyte volumetric capacity (294 Ah l-1) reported to date, which is 5 times that of vanadium catholyte and 3–6 times that of the demonstrated polysulphide flow catholyte. Combining the sulphur flow catholyte with a lithium anode, we can achieve energy density as high as 654 Wh l-1, which is one of the highest energy densities reported for lithium flow batteries. Impregnation of sulphur with the conductive carbon matrix improves the electrical conductivity of the catholyte and enhances the interfacial contacts between the insulating solid sulphur and the carbon matrix, what's more, the viscosity of the flow composite was significantly lower compared with a mechanically mixed suspension. Our concept of impregnating insulating solid active materials with a conductive carbon network offers a promising direction to further increase the energy density and cycling reversibility of RFBs and semi-solid flow batteries.

Introduction

Energy storage system is a critical enabling factor for deploying unstable and intermittent renewable power sources, such as solar and wind power sources. Redox flow batteries (RFBs) are promising technologies for large-scale electricity storage, owing to its design flexibility in decoupling power and energy capacity. However, the RFBs have been suffering from low energy density and low volumetric capacity, which significantly decreases its competitiveness for both stationary and transportation applications.

Increasing the energy density and volumetric capacity of RFBs has been one of the major research efforts for RFBs and has motivated many excellent researchers to put a lot of efforts on new types RFBs. The capacity of the most commercial used all vanadium flow battery is improved to 60 Ah l-1. However, the energy density of RFBs is still much lower than the Li-ion battery (250-300 Wh L-1).

High-energy-density Sulphur-impregnated cathode flow batteries

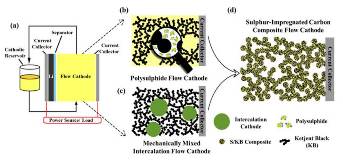

In order to further increase the energy density of RFBs, A new type of semi-solid redox flow battery which is based on a sulphur-impregnated carbon, is demonstrated (Fig. 1). The design of sulphur-impregnated carbon composite flow cathode offers three unique advantages compared with the existing approaches. First, it exploits solid elemental sulphur as the active material which increases the volumetric capacity of the flow cathode by 22.5% compared with polysulphide phase. Second, we impregnate sulphur with KB carbon rather than the conventional mechanical mixing approach reported for intercalation compounds and we show that exploiting the sulphur-impregnated catholyte uniformly integrates the active materials (solid sulphur) and the conductive carbon-percolating network (KB), which enhances the utilization of insulating sulphur. Third, the viscosity of the S/C composite catholyte is significantly lower than the mechanically mixed catholyte. The reduced suspension viscosity significantly increases the maximum allowable concentration of sulphur in the catholyte, which boosts the theoretical volumetric capacity of the flow cathode.

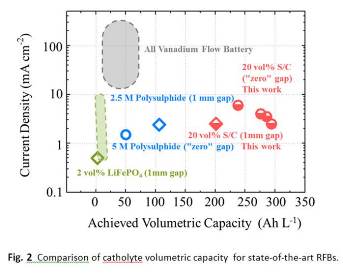

In this study, our design employs sulphur-impregnated carbon (S/C) composite as a flow cathode to achieve high-energy lithium-flow batteries with catholyte volumetric capacity ranging between 294 and 192 Ah l-1 at various current densities with long cycle life (>100 cycles), high columbic efficiency (90–94.5% at 100th cycle) and energy efficiency (82–83.7% at 100th cycle). The demonstrated catholyte volumetric capacity is >5 times higher than the state-of-the-art vanadium flow battery (60 Ah l-1) and 3–6 times higher than the demonstrated Li-polysulphide approach (50–117 Ah l-1), which was shown in Fig. 2.

Conclusion

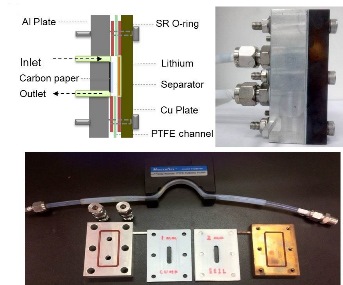

As demands for energy grows and the effects of global climate change becomes more acute, the need to replace traditional fossil fuel with alternative energy sources that are both clean and renewable also becomes urgent. In order to meet the requirement of new energy storage system and increase the competiveness of RFBs, Prof. Yi-Chun Lu and her research team proposed a new type of semi-solid redox flow battery which is based on a sulphur-impregnated carbon (Fig. 3), this new flow cathode design can substantially improve the volumetric capacity and energy density of RFBs. We believe that this method can increase the competitiveness of RFBs for both stationary and transportation applications.

The highly concentrated (20 vol% S, 12.9M [S]) sulphur-impregnated carbon composite catholyte introduced in this work demonstrates substantial improvement in volumetric capacity compared with other existing aqueous and nonaqueous flow chemistries. In addition, the solid-sulphur flow cathode exhibits similar power capability compared with other nonaqueous semi-solid flow chemistries, and alleviates contact issues between insulating active materials and the conductive carbon network. The approach achieves high-energy lithium-flow batteries with catholyte volumetric capacity ranging between 294 and 192 Ah l-1 at various current densities with long cycle life (>100 cycles), high columbic efficiency (90–94.5% at 100th cycle) and energy efficiency (82–83.7% at 100th cycle).

Our concept of impregnating insulating solid active materials with a conductive carbon network offers a promising direction to further increase the energy density and cycling reversibility of RFBs and semi-solid flow batteries.

Research sites and references:

www.nature.com/ncomms/2015/150107/ncomms6877/full/ncomms6877.html

https://sites.google.com/site/yichunlu618/home

|